- Company

- Products

- Solutions

- Applications

- Contact

Corrosion inhibitors help extend the service life of the plant components. This is very important, particularly for the sugar and ethanol industry, where residual materials with high sulfate content are used.

Application: The hydrogen sulfide gas (H₂S) produced in biogas plants can significantly corrode components, especially when using sulfate-containing substrates.

Application format: The LITHSOLVENT corrosion inhibitors series includes special inhibitors designed to reduce the wear and corrosion of metallic plant components such as piping and heat exchangers. This increases plant integrity and service life, which is especially important in the sugar industry and municipal plants with highly contaminated substrates.

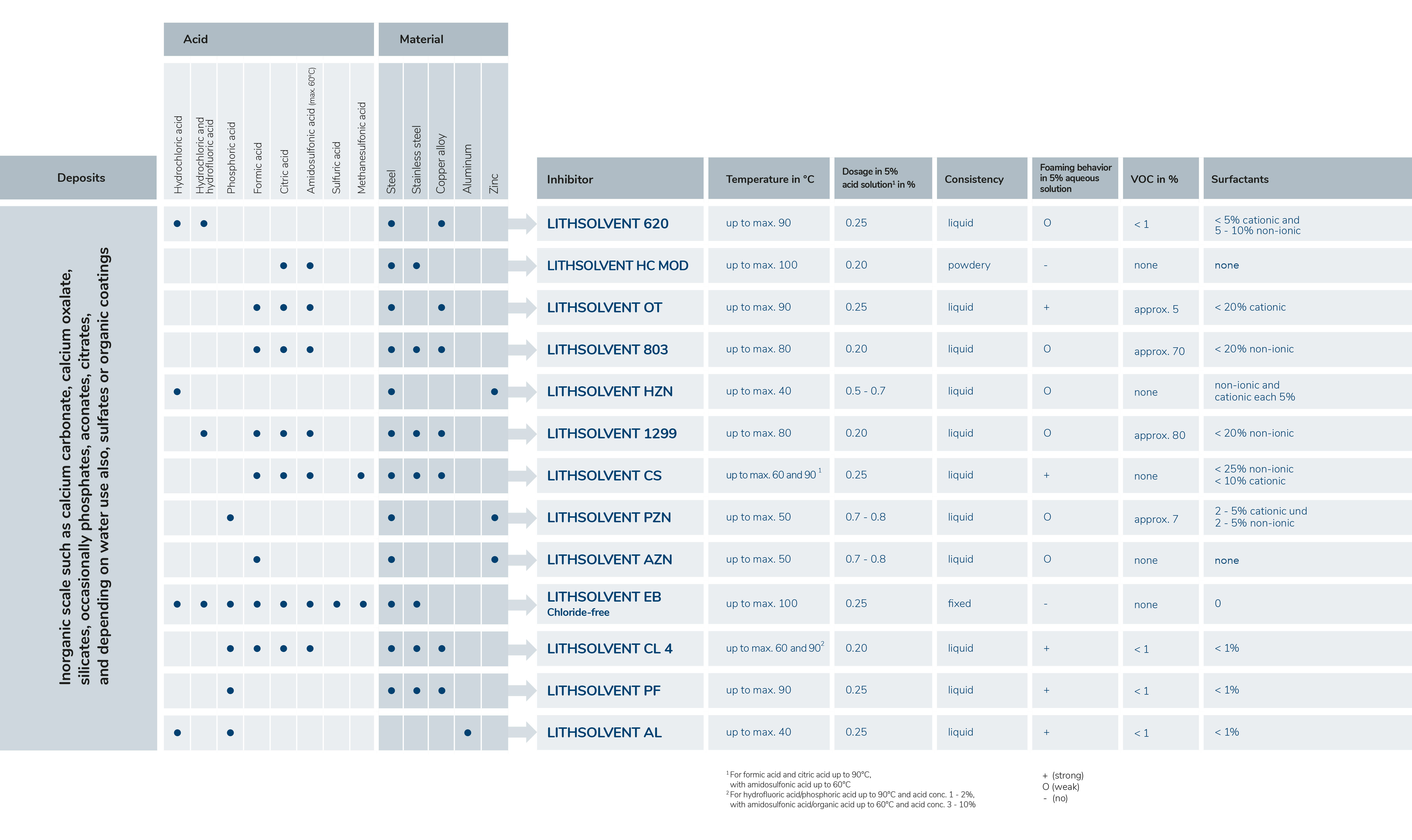

Our LITHSOLVENT series of corrosion inhibitors contains other corrosion inhibitors, depending on the cleaner’s application.

LITHSOLVENT CL 4 is a formaldehyde-free, highly effective corrosion inhibitor specially formulated to protect metallic materials in acidic environments, especially where sulfuric acid is present. Its properties make it an optimal choice for the cleaning and maintenance of components (tank lines, supply and discharge lines) in biogas plants where deposits and corrosion protection are critical.

Benefits for biogas plants:

LITHSOLVENT CL 4 is ideal for chemically cleaning the following:

See a selection of Corrosion inhibitors of our portfolio or take a look here: LITHSOLVENT Series.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.