- Company

- Products

- Solutions

- Applications

- Contact

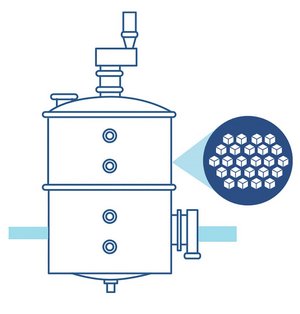

Crystallization is a natural process of which almost all pure substances are capable. In the process, the substances enter a state of higher order in order to escape the chaos of their environment. On the one hand, this process takes place spontaneously in nature, for example when salt crystals form on evaporating pools of seawater or when lava solidifies and forms basalt columns. On the other hand, both in the chemical-pharmaceutical industry and in the food industry, crystallization is specifically brought about and controlled in order to obtain the desired active ingredients, drugs and foodstuffs in the desired quality.

Generally, crystallization is used here for purification, separation and extraction of the desired raw materials. Crystallization is also a quality-determining process in sugar production and refineries. Effective and efficient crystallization ensures high quality and safe production.

In the pursuit of optimum crystal quality and maximum yield, certain measured values play a decisive role. They allow precise monitoring and control throughout the crystallization process. This allows the process parameters to be adjusted specifically and ensures efficient control.

The CV value - A look at the variation in crystal sizes

The CV value provides information about the degree of variation in the crystal size distribution in a sample. A low CV value indicates a low variation in crystal size, which is often desired in the food industry. This is because a uniform crystal size leads to a better texture and higher quality of the final product. A high CV value, on the other hand, indicates a greater variation in crystal size, which may be undesirable and may result in uneven texture or other undesirable properties of the final product. The CV value is calculated by dividing the standard deviations of the crystal sizes by the average of the crystal sizes, and then multiplying by 100.

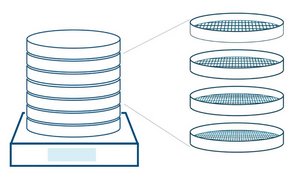

The MA Value - The Mean Mesh Size as the key to optimal yield

The mean mesh size (MA) indicates the size of the opening of a sieve through which 50 percent of the sample crystals fall and 50 percent remain. The MA test can be used to determine which particle sizes are retained by a series of sieves. The results are plotted on a graph showing the sieve openings along a straight line. This diagram can be used to determine the MA and CV. In general, coarse crystals are easier to centrifuge and provide a better yield. Very fine crystals, on the other hand, easily pass through the centrifuge sieve and remain in the mother liquor, which must be recrystallized. This reduces the yield. Small crystals are more soluble than large crystals at the same temperature. Therefore, fine sugar is more demanding for industrial purposes

The fine dust content – quality and safety in mind

A high fine dust content is undesirable during crystallization, but cannot be completely avoided. Increased fines content may indicate impurities or incomplete separation of sugar crystals and mother liquor. In addition, a high dust content can lead to deflagration and poses a potential explosion risk. Therefore, it is of great importance to regularly monitor the level of particulate matter to ensure product quality while maintaining safety.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.